Bioindustrial Technologies

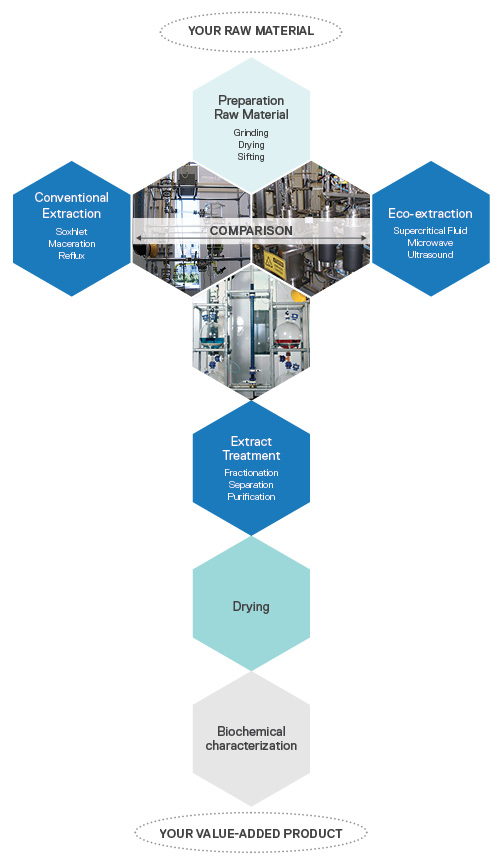

CÉPROCQ ‘s expertise allows you to offer the methods best suited to your requests for extraction of high value-added compounds:

- Development of every step of a pilot-scale extraction process, from preparation of the raw material to forming and characterization of the extract;

- Comparative studies of different pilot-scale extraction methods (example: comparison of an oil from marine biomass extracted by Soxhlet and by supercritical fluids);

- Valorization of extraction residues to develop processes of conversion and transformation to zero residue (example: extraction of bioactive molecules from a residue resulting from extraction of an algal oil.)

Conferences

Since 2012, CÉPROCQ has had an NSERC Industrial Research Chair for Colleges in Agroforestry Extraction, directed by Yacine Boumghar, Director of CÉPROCQ. This Chair is a centre of convergence of knowledge of agroforestry extraction and an incubator of technological solutions to meet the needs of the community and industrial players.

In relation to the Chair, CÉPROCQ researchers are called on to make presentations and moderate many conferences.

Un procédé Organosolv à l’éthanol/eau catalysé au chlorure de fer pour la production de lignines, de cellulose et de dérivés de haute qualité

Presented at 71e Conférence canadienne sur le génie chimique (CCEC 2021), Montreal, 27 october 2021

Y. Boumghar, C. Bruel, N. El Mehdi, C. Levasseur

Extraction comparative des cannabinoïdes

Presented at 71e Conférence canadienne sur le génie chimique (CCEC 2021), Montreal, 26 october 2021

Y. Boumghar, N. El Mehdi, M. Sarrazin

Experimental and computer aided solubility quantification of diverse lignins and performance prediction

Ajao, O., Benali, M., & El Mehdi, N. (2021) The Royal Society of Chemistry. DOI: 10.1039/d0cc04228e

Acetone–Butanol–Ethanol Production from Eastern Canadian Yellow Birch and Screening of Isopropanol–Butanol–Ethanol-Producing Strains.

Benali, M., Ajao, O., El Mehdi, N., Restrepo, A. M., Fradj, N., & Boumghar, Y. (2019). Industrial Biotechnology, 15 (3), 188-201.

Recovery of sugars from lignocellulosic residues and their conversion into biobutanol and coproducts: ABE fermentation and perspectives on paradigm shift

Presented at the BIOFOR International Conference, Montreal, Canada, 2019

Olumoye Ajao, Andrea M. Restrepo, Naima El Mehdi, Marzouk Benali, Simon Bernabé, and Yacine Boumghar

Lignin Properties: Towards standardized methods, protocols and policies

Presented at the BIOFOR International Conference, Montreal, Canada, 2018

Olumoye Ajao, Jawad Jeaidi, Marzouk Benali, Andrea M. Restrepo, Naima El Mehdi, and Yacine Boumghar

Production du BIObutanol et d’acides organiques à partir du Bouleau jaune

Presented at the Colloque étudiant 2018 — Réalisons la transition vers la bioéconomie, Campus de l’UQTR à Drummondville, Canada, 2018

Andrea M. Restrepo, Olumoye Ajao, Naima El Mehdi, Simon Barnabé, and Yacine Boumghar

Lignin analytics: variability, challenges with the methods, and opportunities

Presented at the 8th Nordic Wood Biorefinery Conference, Helsinki, Finland, 2018

Marzouk Benali, Olumoye Ajao, Jawad Jeaidi, Andrea M. Restrepo, Naima El Mehdi, and Yacine Boumghar

Solubility and compatibility of various lignins in solvents and polymers: experimental and computer-based evaluation

Presented at the 8th Nordic Wood Biorefinery Conference, Helsinki, Finland, 2018

Olumoye Ajao, Jawad Jeaidi, Marzouk Benali, Naima El Mehdi, Andrea M. Restrepo, and Yacine Boumghar

Optical properties of lignins and their importance in lignin derivatives development

Presented at the First PAPTAC International Lignin Conference, Edmonton, Canada, 2018

Jawad Jeaidi, Olumoye Ajao, Marzouk Benali, Andrea M. Restrepo, Naima El Mehdi, and Yacine Boumghar

Quantification and Variability Analysis of Lignin Optical Properties for Colour-Dependent Industrial Applications

Molecules, vol. 23, no. 2, p. 377, Feb. 2018

O. Ajao, J. Jeaidi, M. Benali, A. M. Restrepo, N. El Mehdi, and Y. Boumghar

Mapping lignin properties as a strategy to develop its valorisation pathways

Presented at the International Bioenergy & Bioproducts Conference, Norfolk, USA, 2017

Olumoye Ajao, Jawad Jeaidi, Marzouk Benali, Andrea M. Restrepo, Naima El Mehdi, and Yacine Boumghar

Characterization of lignin from different sources: Variability of lignin color and its impacts on quality control of bio-based production processes

Presented at the BIOFOR International Conference, Montreal, Canada, 2017

Olumoye Ajao, Jawad Jeaidi, Andrea M. Restrepo, Marzouk Benali, and Yacine Boumghar

Effect of Process Conditions on Lignin Colour: a Carbon Black Case Study

Presented at the 7th Nordic Wood Biorefinery Conference, Stockholm, Sweden, 2017, pp. 68–73

Olumoye Ajao, Jawad Jeaidi, Andrea M. Restrepo, Naima El Mehdi, Marzouk Benali, and Yacine Boumghar

Yellow birch transformation into butanol and organic acids in an integrated biorefinery platform

Presented at the 6th Nordic Wood Biorefinery Conference, Helsinki, Finland, 2015, pp. 255–259

Olumoye Ajao, Andrea M. Restrepo, Naima El Mehdi, Yacine Boumghar, and Marzouk Benali

Production of Butanol and Organic Acids in an Integrated Biorefinery Platform

Presented at the BiofuelNet Advanced Biofuels Symposium, Montreal, Canada, 2015

Olumoye Ajao, Andrea M. Restrepo, Naima El Mehdi, Yacine Boumghar, and Marzouk Benali

Benchmarking of Lignocellulosic Biomass Pretreatment: Performance and Energy Requirements

International Forest Biorefinery Summit, Montréal, February 2015

C. Hertz, M. Benali, Y. Boumghar, J. Jeaidi

Anaerobic Fermentation of Sugar-rich Streams to Simultaneously Produce Biobutanol and Organic Bio-acids: Mixed Sugar Model and Yellow Birch-based Sugars Case Studies

International Forest Biorefinery Summit, Montréal, February 2015

A. M. Restrepo, N. El Mehdi, Y. Boumghar, M. Benali

Supercritical CO2 as an innovative and viable process

Colloque chimie verte et procédés durables (Colloquium on green chemistry and sustainable processes), Boucherville, October 2014

M. Sarrazin, Y. Boumghar

Fungal bioconversion of betulinol into betulinic acid

Colloque sur les champignons forestiers et autre PFNL : innovations et perspectives (Colloquium on forest mushrooms and other NTFPs: innovations and perspectives), La Pocatière, August 2014

S. Abdeladim, Y. Boumghar, M. Sarrazin, A. Vialle, N. El Mehdi

Micronization of Nordic Berries by Particle from gas saturated solution (PGSS) combined with drying

14th European Meeting on Supercritical Fluids, Marseille, France, May 2014

Y. Boumghar, M. Benali

Extraction processes

Séminaire sur les végétaux (Seminar on plants), UQAC, Chicoutimi, April 2014

Y. Boumghar

Development of ecoextractions for valorization of yellow birch bark

Atelier des experts du réseau Trans-tech (Workshop of Réseau Trans-tech experts), Québec, April 2014

N. El Mehdi, M. Sarrazin, Y. Boumghar

Potential of yellow birch bark, extractable forest products: a promising avenue for the Québec forest industry

Trois-Rivières, February 2014

Y. Boumghar