Equipment

Barre latérale

Transformation Equipment and Methods

Liquid-liquid extraction pilot unit

In most bioindustrial processes, the raw materials must be treated to obtain a pure extract with the desired properties. The liquid-liquid extraction pilot unit with a Karr™ agitated column allows to treat 20 liters of liquid extract.

Laboratory scale spray dryer

Spray drying is a dehydration technology for suspended or dissolved materials. Unlike the traditional drying in an oven, through spray drying, the sample spends only a few seconds (1 - 1.5 sec) in a high temperature zone. Therefore, it is highly recommended for drying temperature-sensitive materials (e.g. antioxidants). CÉPROCQ has a laboratory scale spray dryer unit: Buchi Mini Spray Dryer B-290™. It is a laboratory equipment capable of drying up to 30 ml/min of an aqueous solution. The output particle size could be adjusted between 2 and 25 μm.

Pilot scale spray drayer

At CÉPROCQ, we have access to the pilot spray dryer unit : GEA Niro Spray Dryer™. This is a pilot scale spray dryer with a maximum water evaporation rate of 6 kg / h. The system is equipped with a rotating atomizer at a speed of 20 000 - 50 000 RPM. Thanks to this atomizer, very small droplets are generated, which requires a short residence time in the drying chamber. Two cyclones at the outlet of the drying chamber allow the maximum recovery of the powders.

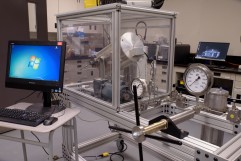

Pilot unit for subcritical water extraction

The pilot unit of subcritical water extraction has been fabricated at CEPROCQ. This type of extraction takes place at temperatures between the boiling point and the critical point of water (374.1 ° C, 221 bar), with enough pressure to keep the water in the liquid state and allow to extract polar and less polar compounds. This technique is emerging as a promising and powerful alternative to conventional techniques and is a breakthrough in finding alternatives to organic solvents.

Instant Controlled Pressure Drop system

The Instant Controlled Pressure Drop system applies a high-pressure steam (maximum 9 bar) in a short period of time. An extremely fast depressurization (less than 200 ms) is then applied which gives the treated product an attractive and new texture. In addition, the formation of pores in the product accelerates its drying leading to an important energy saving. This technique could be used as:

- Assisted drying

- Decontamination

- Extraction

- Lignocellulosic pre-treatment

- Essential oils extraction

Pilot unit for advanced oxidation (AOP)

To treat industrial and agricultural wastewater, CÉPROCQ uses advanced oxidation technologies (ozone, hydrogen peroxide, ultraviolet). Creating highly oxidizing entities (such as hydroxyl radicals) allows destruction of a wide range of nonbiodegradable organic compounds. An in-house fabricated pilot unit facilitates applying these three oxidants separately or in combinations for treatment of wastewater. The unit could be used for treatment of 10 to 30 litres wastewater.

Pilot unit of membrane extraction

The hollow fiber membrane contactor makes it possible to extract and concentrate metal ions and organic molecules by liquid-liquid extraction, or inorganic molecules like ammonia by liquid-gas-liquid extraction. The unity of CEPROCQ can treat 60 liters / hour of effluent. However, its capacity can be increased by using larger contactors. The basic treatment unit includes two tanks, two peristaltic pumps and one contactor, which can be assembled quickly on site to evaluate its potential.

Total carbon analyzer

The TOC analysis shows the total amount of organic carbon in municipal wastewater, industrial wastewater, and process water. This analysis is generally used to know the rate of pollution of a water or to monitor the effectiveness of its treatment. TOC measurement is based on: 1) the oxidation of organic carbon to carbon dioxide, and 2) the measurement of carbon dioxide generated by infrared. Ability to measure Total Carbon (TC), Inorganic Carbon (IC), and Total organic Carbon (TOC, by TC-IC difference) and Total Nitrogen (TNb). Range from 4 μg / l to 30,000 mg /l (Shimadzu TOC-L Series device™).

Specific surface area (BET) and porosity analyzer

The Micrometrics Tristar II analyzer™ is used for determination of specific surface area of solids and porous materials such as biochar or lignin. Moreover, it could be used to measure the total pore volume and the pore size distribution of a solid sample. The analyzer works with both CO2 and N2 isotherms. In addition, the analyzer is equipped with a three-station degasser, which allows the user to degas 3 samples at the same time. Three analysis stations allow the operator to perform a triplicate analysis in one step.

| Parameter | Detection limit |

| Specific surface (m2/g) | ≥ 0,01 |

| Total area surface (m2) | ≥ 0,1 |

| Pore volume (cm3/g) | ≥ 4×10-6 |

Particle size analyzer

It is a FRITSCH Nanotec™ particle size analyzer by laser light scattering technology. The wet and dry mode allow us to measure the particle size distribution of a solid and a suspension. The measuring range is 0.01 to 2100 μm for suspension and 0.1 to 2100 μm in dry mode.

FTIR (Fourier Transform Infrared Spectroscopy)

FTIR can characterize a solid or liquid product (Nicolet iS50 FTIR™ device) . It is a non-destructive technique, which does not require sample preparation, except grinding for solids samples. The resulting spectrum reflects the molecular vibrations under the light effect as a function of wavelength. The results are the peaks related to functions of the molecule such as OH, CH, C = O, COO-, C = C, C≡C, C≡N, NH, NH2, etc. This technique makes it possible to characterize organic compounds as well as inorganic ones. Although it is a qualitative method, it can be used for quantitative measurement under certain conditions.

Spectrophotometry equipment

A.1 The Shimadzu model UV-1700 PharmaSep™ spectrophotometer allows the determination of the concentration of a chemical entity in solution, using the Beer-Lambert law. It could be used to determine the percentage of sugars, polyphenols and of proteins. A.2 The Perkins Elmer VICTOR ™ X3™ Plate Reader is a platform for the quantitative detection of light emitting or absorbing markers. The device also includes an improved software package that includes a better start-up wizard, easier protocol creation, temperature control, improved kinetic support for analysis, a stirring system, and an excitation filter wheel, and with 8-position emission.

HPLC Q-TOF

The Q-TOF detector can identify and quantify molecules at very low concentration, as well as unknown molecules.

High performance liquid chromatography (HPLC)

High performance liquid chromatography (HPLC) is an analytical technique used to separate molecules from a complex mixture in a column. Once the molecules have been separated, they enter a detector. To quantify molecules, this device has conventional detectors such as a UV-Visible spectrometer (DAD diode Array detector), a fluorescence detector as well as refractive index detectors (RID). By applying these detectors, a wide range of molecules such as sugars, pharmaceutical molecules, polyphenols could be quantified. Moreover, the size of molecules, such as lignin could be determined.

Gas chromatography

Gas chromatography (GC) is a very effective technique for analyzing volatile and non-labile molecules in liquids and gases. The gas chromatograph coupled with a mass spectrometer (GC-MS) could be used to identify unknown molecules using a database containing more than 267,000 compounds. This technique could determine the composition of products obtained from biorefining, catalytic processes, pyrolysis. In addition, a special database has been added to quickly determine the composition of any essential oil. A whole range of injectors and detectors are available to analyze many different samples. various injection including split / splitless, on column, Solid Phase Micro Extraction (SPME) injections could be performed. The unit is also equipped with a gas injector. Specific detectors such as NPD, ECD, FPD can be also installed. The flame ionization detector (FID) is mainly used to quantify catalysis products, food extracts or solvents and the thermal conductivity detector is used to quantify gases ranging from simple gases such as CO2 or methane to more complex gases.

Karl Fischer titrator

Mettler Toledo's Karl Fisher C20 titrator™ allows us to determine the amount of water present in a sample. This titrator uses the coulometric method, a titration method in which the titration agent is produced in a solution by electrolysis and the required quantity of the agent is determined by measuring the number of coulombs used to prepare it. The coulometric cell consists of two parts, the anode and the cathode, separated by a diaphragm. The amount of water titrated by the coulometric technique is determined by the amount of Coulomb current used to generate the Iodine. This type of titration is more applicable in the food and petrochemical fields. It can be used for determination of the water content of oils, mineral oils, edible fats and fats.

Viscometer

Viscosity is the resistance to movement of a fluid for flow with or without turbulence. The higher the resistance, the greater the force required to cause this movement, the thicker the substance. The Brookfield™ type viscometer could be used to measure this resistance. The principle of a viscometer is to rotate a needle in a fluid. This viscosity, measured by imposing a speed of rotation, is a dynamic viscosity that is expressed in mPa.s or cPoise This analysis can be used to: control the quality of any fluid; monitor polymerization reactions; control the viscosity of paints. It is applicable in the chemical and petrochemical, food, pharmaceutical industries.

Laboratory scale bioreactor

The BioFlo 110TM is a bench-top fermenter suitable for all levels of research and development. It has an easy-to-use control interface, as well as modules and other accessories to meet various specific needs. It is possible to define setpoints for pH and dissolved oxygen (DO), which can be controlled by addition of a gas, an acid or a base with the cascade function. Two fermenters with a working capacity between 0.4 L and 1 L are available.

Semi-pilot scale bioreactor

Labfors 5 TM is an easy-to-use bench-top bioreactor. Different culture strategies such as batch culture, fed-batch and continuous modes could be applied. The touch screen provides precise and reliable control and communication with the IRIS supervision software. CÉPROCQ has a reactor with two interchangeable tanks with a capacity of 3.6 L and 7.5 L with working volumes of 2.3 L and 5 L.

Freeze-drying at laboratory scale

Freeze-drying (lyophilization) is a method of removing water by sublimation of the ice crystals from the frozen material. The process allows a better-quality products, compared to products dried with traditional methods. CÉPROCQ has a bench-top freeze dryer: VirTis Bench Top K TM series freeze dryer. It can support up to 12 glass bottles with a capacity ranging from 10 ml to 300 ml.

Freeze-drying at pilot scale

Freeze-drying (lyophilization) is a method of removing water by sublimation of the ice crystals from the frozen material. The process allows a better-quality products, compared to products dried with traditional methods. CÉPROCQ has a pilot freeze dryer: VirTis Genesis 35LTM pilot freeze dryer. It is designed to meet all the requirements of freeze drying, such as storage temperature as low as -70 ° C and condenser temperature up to -85 ° C. It has 4 shelves that can accept trays of 3 L each. The unit is equipped with a control system and temperature and vacuum sensors, in order to configure the conditions of freeze-drying, according to the requirements of the application.

Pilot scale homogenizer

The Microfluidizer processor M-110EH TM uses high shear fluid processing technology to reduce the size of droplets, particles and cell lysis. It has a fixed geometry interaction chamber and a ceramic piston (zirconia), which can handle a wide variety of fluids. Lysis is the destruction of the cell membrane and homogenization is one of the methods of preparing lysates (products of decay). The pressure applied can reach up to 30,000 psi. A sample can be processed in a single "pass" through the chamber or continuously in several passes.

Liquid-liquid extraction pilot unit

Liquid-liquid extraction pilot unit Laboratory scale spray dryer

Laboratory scale spray dryer Pilot scale spray drayer

Pilot scale spray drayer Pilot unit for subcritical water extraction

Pilot unit for subcritical water extraction Instant Controlled Pressure Drop system

Instant Controlled Pressure Drop system Pilot unit for advanced oxidation (AOP)

Pilot unit for advanced oxidation (AOP) Pilot unit of membrane extraction

Pilot unit of membrane extraction Total carbon analyzer

Total carbon analyzer Specific surface area (BET) and porosity analyzer

Specific surface area (BET) and porosity analyzer Particle size analyzer

Particle size analyzer FTIR (Fourier Transform Infrared Spectroscopy)

FTIR (Fourier Transform Infrared Spectroscopy) Spectrophotometry equipment

Spectrophotometry equipment HPLC Q-TOF

HPLC Q-TOF High performance liquid chromatography (HPLC)

High performance liquid chromatography (HPLC) Gas chromatography

Gas chromatography Karl Fischer titrator

Karl Fischer titrator Viscometer

Viscometer Laboratory scale bioreactor

Laboratory scale bioreactor Semi-pilot scale bioreactor

Semi-pilot scale bioreactor Freeze-drying at laboratory scale

Freeze-drying at laboratory scale Freeze-drying at pilot scale

Freeze-drying at pilot scale Pilot scale homogenizer

Pilot scale homogenizer